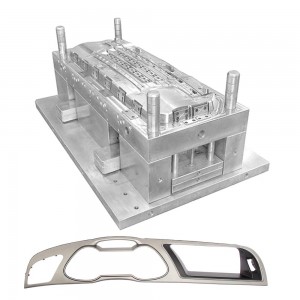

Auto parts injection mold

Tsanangudzo

1. Kudurura hurongwa

Inoreva chikamu chegwara rekuyerera pamberi pepurasitiki yapinda mugomba kubva mumuromo, kusanganisira iyo huru yekuyerera chiteshi, gomba rekudya rinotonhora, diverter, uye gedhi, pakati pevamwe.

2. Molding parts system:

Inoreva kusanganiswa kwezvikamu zvakasiyana-siyana zvinoumba chimiro chechigadzirwa, kusanganisira kufamba kufa, kufa kwakagadziriswa uye mhango (concave kufa), musimboti (punch kufa), tsvimbo yekuumba, nezvimwewo. chimiro chekunze chemukati (concave die) chinoumbwa.Mushure mekuvharwa kwefa, mhango nemhango zvinogadzira mhango inofa.Dzimwe nguva, zvinoenderana nemaitiro uye zvinodiwa zvekugadzira, iyo yakakosha uye inofa inogadzirwa kubva musanganiswa wezvivharo zvekushanda, kazhinji kubva pachidimbu chimwe chete, uye chete muzvikamu zvinokuvara zviri nyore uye zvakaoma-kushanda zvekuisa.

3, iyo tembiricha yekudzora system.

Kuti usangane neiyo jekiseni process tembiricha zvinodiwa zvefa, zvinodikanwa kuve netembiricha yekudzora tembiricha yekudzora tembiricha yefa.Kune thermoplastic jekiseni mold, iyo huru dhizaini yeinotonhora sisitimu yekutonhodza mold (inogona zvakare kudziyisa mold).Nzira yakajairika yekutonhodza mold ndeyekumisa mugero wemvura inotonhorera muforoma uye kushandisa inotenderera inotonhorera mvura kubvisa kupisa kubva muforoma.Pamusoro pekupisa mold, mvura inotonhorera inogona kushandiswa kupfuudza mvura inopisa kana mafuta anopisa, uye magetsi ekudziya emagetsi anogona kuiswa mukati nekutenderedza mold.